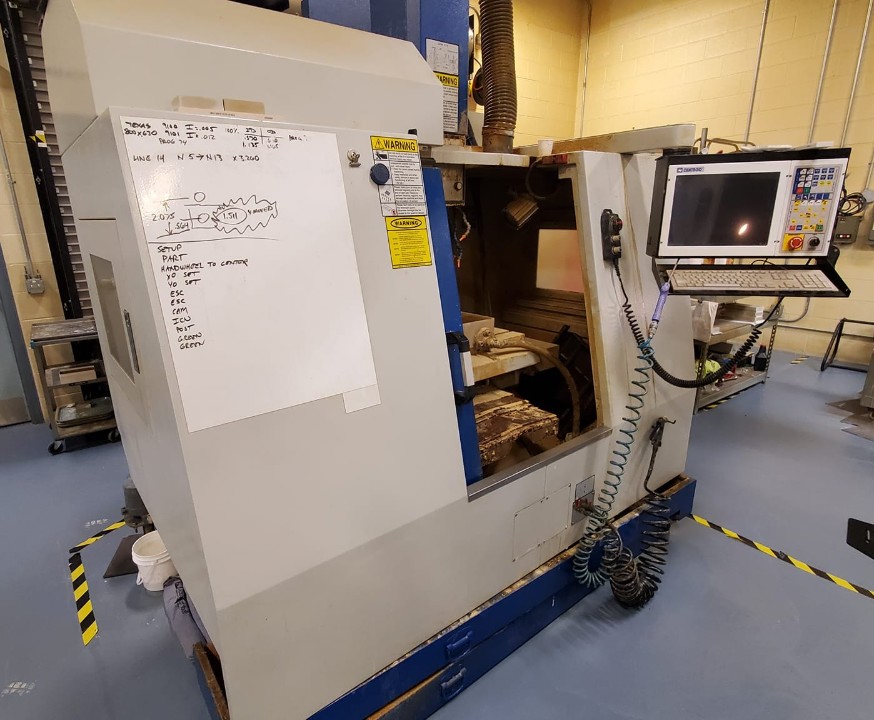

ATRUMP E216 Maxi-Mill

Called in to do ball screw and end bearing service on an ATRUMP E216 Maxi-Mill. The X-Axis of this machine was extremely noisy, making a cement mixer noise when the axis was placed on rapid traverse. Inspection and service found that the end bearings were shot. The Hiwin ball screw was worn.

The main culprit behind the X Axis noise issue on a ATRUMP E216 Maxi-Mill. These SKF end bearings made in Austria are what we found in the machine. They were basically shot. BSD 2047COA. We were able to get replacement sets of these bearings overnighted.

The X-Axis ball screw removed from an ATRUMP E216 Maxi-Mill. The ball nut is what Ballscrew Guys calls a “split nut” design. There is a flange ball nut half and an outboard half which combine to make a single ball nut assembly. In the middle, fixed by compression and a keyway, is a spacer shim. This shim, coupled with the proper sized ball bearings, is what establishes and maintains the proper preload and drag torque to the ball screw assembly. Should you ever inspect a ball screw of this design and type, try to move the spacer shim with your finger. If it moves, your ball nut has lost preload and needs to be reballed and serviced. This is a HIWIN ball screw. S140GCF-3 001.