Miyano Mill

Miyano MTV T310 Vertical Mill Center.

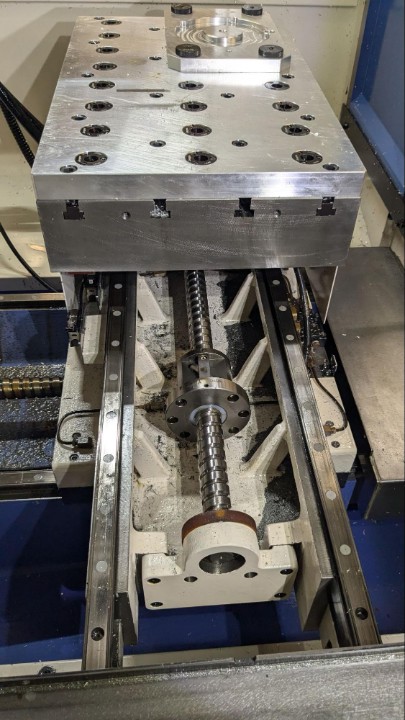

Here, the X and Y-Axis ball screws were shown on a Miyano MTV T310 Vertical Mill Center, similar to the T410 design as well. The protective covers were disconnected and slid back to access the ball nuts. What is interesting about the Miyano ball screw designs is that the ball screw shafts themselves are only fixed by angular contact bearings on the motor side of the screw. The non-drive side of the ball screw shaft is actually only held in place by a rather simple radial bearing, often starved of lubrication. This ball screw setup is good for a Z-Axis on machines that do not utilize violent machine processes because the light support on the outboard end can often translate into visual chatter marks on mill cuts. Often, these cut blemishes are difficult to measure and qualify, but they can be visually seen. Vertical Mill Centers and Tap and Drill CNC machines like the TSV-21 and TSV-31 have similar issues as well. Still, the Miyanos use quality Japanese KOYO ball screw assemblies, which are most often rebuildable in the machine.

This is the X-Axis to a Miyano MTV T310 Vertical Mill Center. It is similar to the MTC T410 and the TSV Tap and Drill Centers, like the TSV-21 and the TSV-31. This one used single ball nut ball screw assemblies made by KOYO in Japan. These ball screws were fairly straightforward in their repair and refurbishment. The main issues found with them were looseness after being run with insufficient lubrication.

This is the Y-Axis to a Miyano MTV T310 Vertical Mill Center. It is similar to the MTC T410 and the TSV Tap and Drill Centers, like the TSV-21 and the TSV-31. Like the X-Axis, this one used single ball nut ball screw assemblies made by KOYO in Japan. The main issues found with them were looseness after being run with insufficient lubrication. If noticed, there was a yellow/brown haze on the assembly. This was dried cutting fluid. It was found that on the Y-Axis of these machines, this dried fluid buildup often acted as an adhesive, holding cut debris to the ball screw shaft, which got sucked up into the ball nut. This, in turn, caused additional drag torque and resistance in spinning. This, in turn, caused the servo motor to do extra work. If excess servo error and overheating alarms were noticed on the Y-Axis, this issue could very well have been the culprit.