Bosch-Rexroth Parts

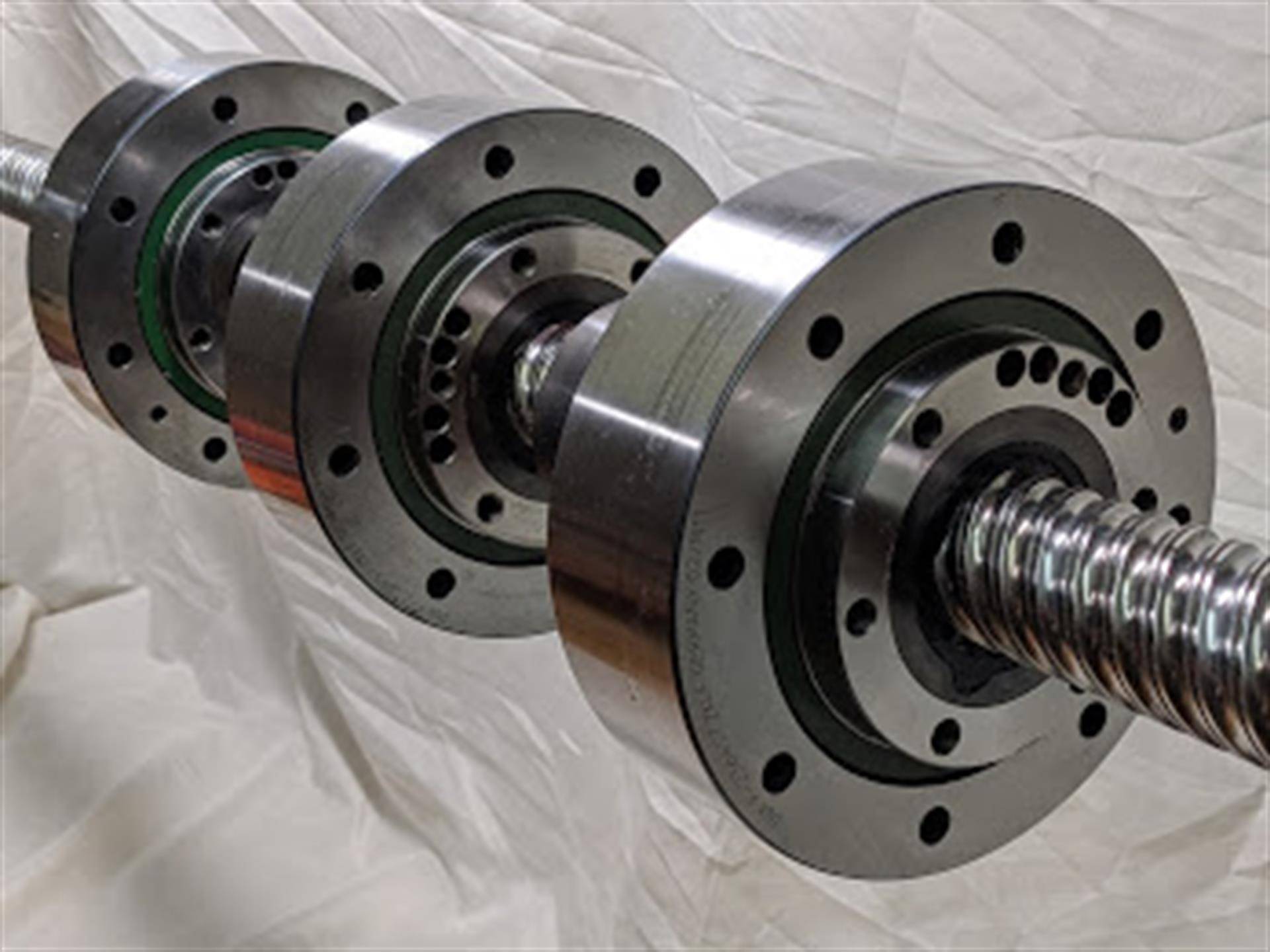

6mm and 6.5mm ball Bosch Rexroth ball nuts with INA rotation bearing. These are the most common Bosch Rexroth ball screw assemblies we refurbish. Most often, found on the X and Y axis of KOMO and Onsrud CNC Routers. We specialize in the repair and reconditioning of ball screws. We utilize our own designs of reinforced seals and ball bearing circulation guide inserts, increasing the operation and longevity of these critical motion system components.

Here, the ball nuts are being fit to verify function rotating on the 4 groove ball screw shaft. What many in the industry do not know is that this ball nut only rides on one of these four helixed bearing raceways. This means that even though you get raceway damage, you can have three more possible tracks to rebuild your ball screw, vastly increasing its lifespan.

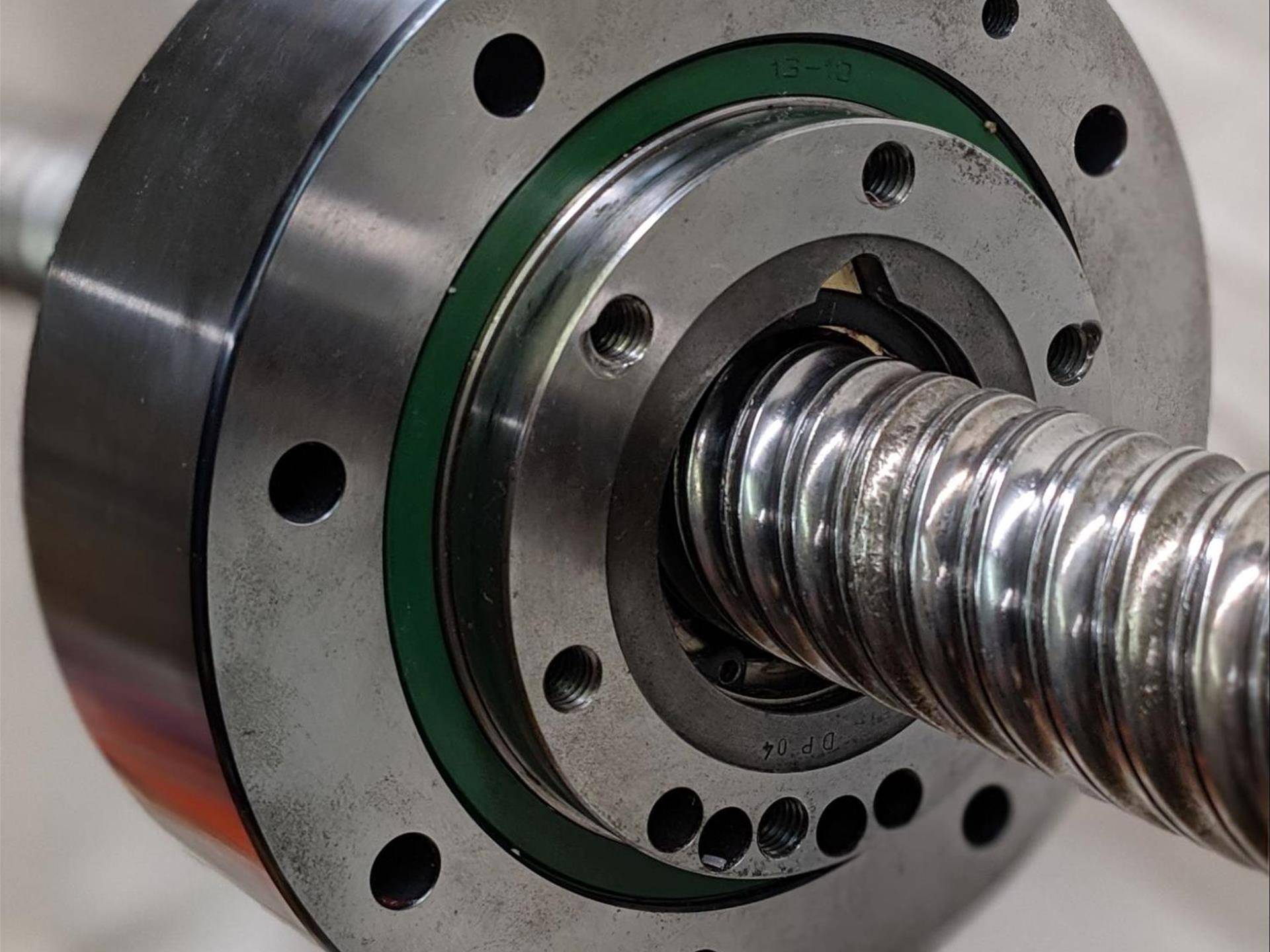

This is a Bosch Rexroth ball nut loaded onto a damaged ball screw. The raceway damage is present on only one of the four raceways. This helps show how that a damaged screw can still be made functional, without buying a whole new assembly. New ball bearings, snap rings, and brass ball bearing recirculation inserts, and seals are installed on an unused bearing trackway. Note that the seal is not installed in this image. Even though the ball screw can be rebuilt with a damaged raceway, great care has to be made to smooth out any existing damaged sections. Usually a combination of grinding, filing, sanding, and polishing.

The essential kit used in refurbishing a Bosch Rexroth ball nut. Chrome Steel ball bearings, two heavy duty brass ball bearing recirculation inserts, two bearing insert retaining snap rings, and two seals. While these are the core parts required, the ball nut and ball screw shaft raceways must still be cleaned and inspected prior to rebuilding. It is common during ball screw crashes or failures that raceway damage has occurred. These must be located and removed as a travel hazard of the motion system component’s path.

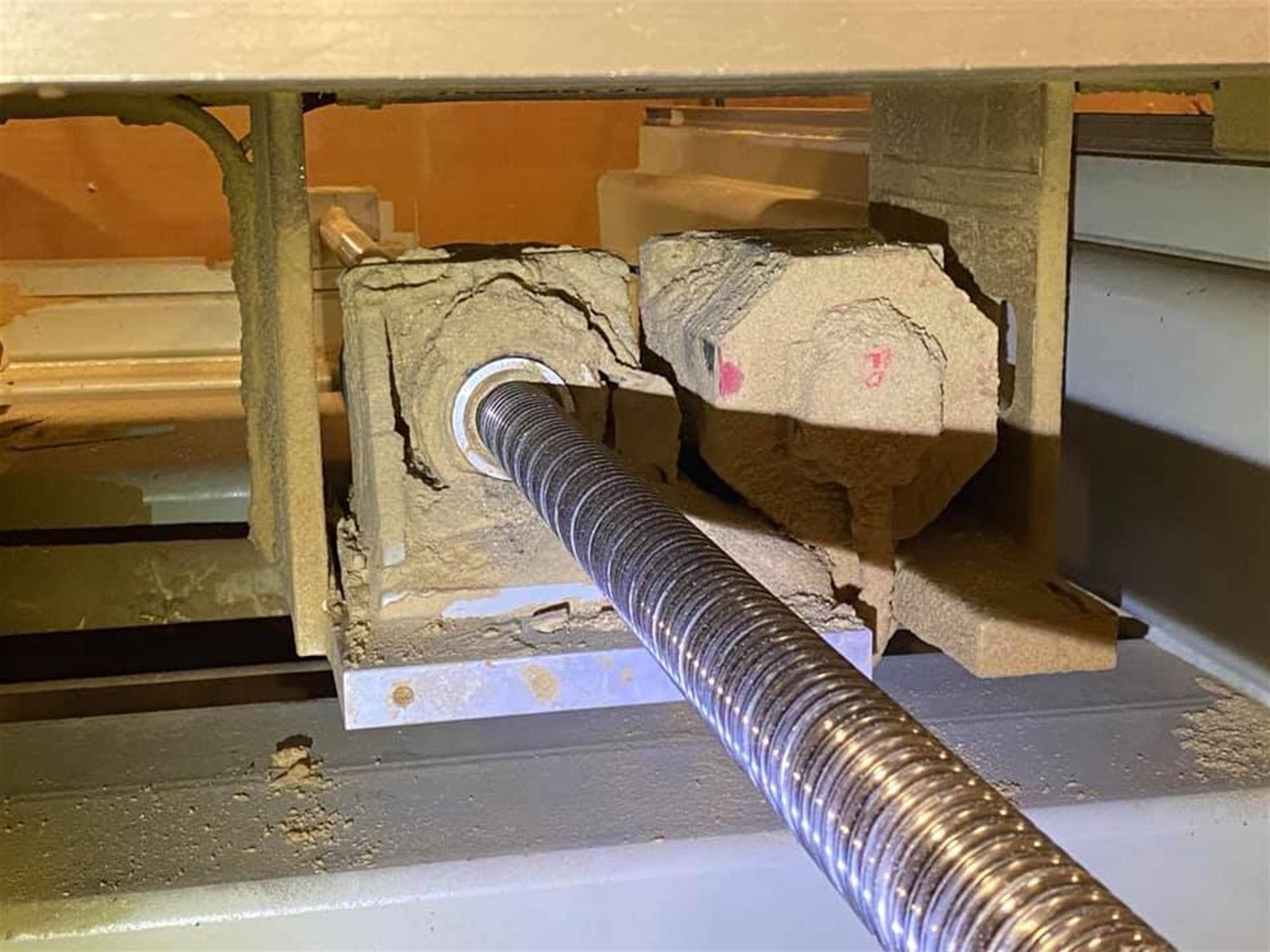

The main reason Bosch Rexroth ball screws fail in KOMO and Onsrud routers is debris compacting inside the nut interfering with ball bearing rotation. Sawdust and debris from routing sticks to lubricant on the ball screw shaft and gets carried into the nut. Over time, it completely fills up the ball nut, blocking lubrication ports. Eventually the ball bearings either seize or destroy the OEM plastic ball bearing circulation guide inserts. It is critical to keep these areas clean in a preventative maintenance and cleaning program otherwise your motion control systems will clog and fail prematurely.