Komo Fusion

The KOMO Fusion Routers are popular because of their cut speed. The reality is that they use nearly the same motion system components as older generations but with larger servo drives that move all the axes faster. The faster speeds are often beyond the recommended upper threshold in the blueprint specifications of Bosch Rexroth ball screws. Excessive speed coupled with poor lubrication and contamination is what kills KOMO motion systems components. It is critical that preventative maintenance and cleaning is done.

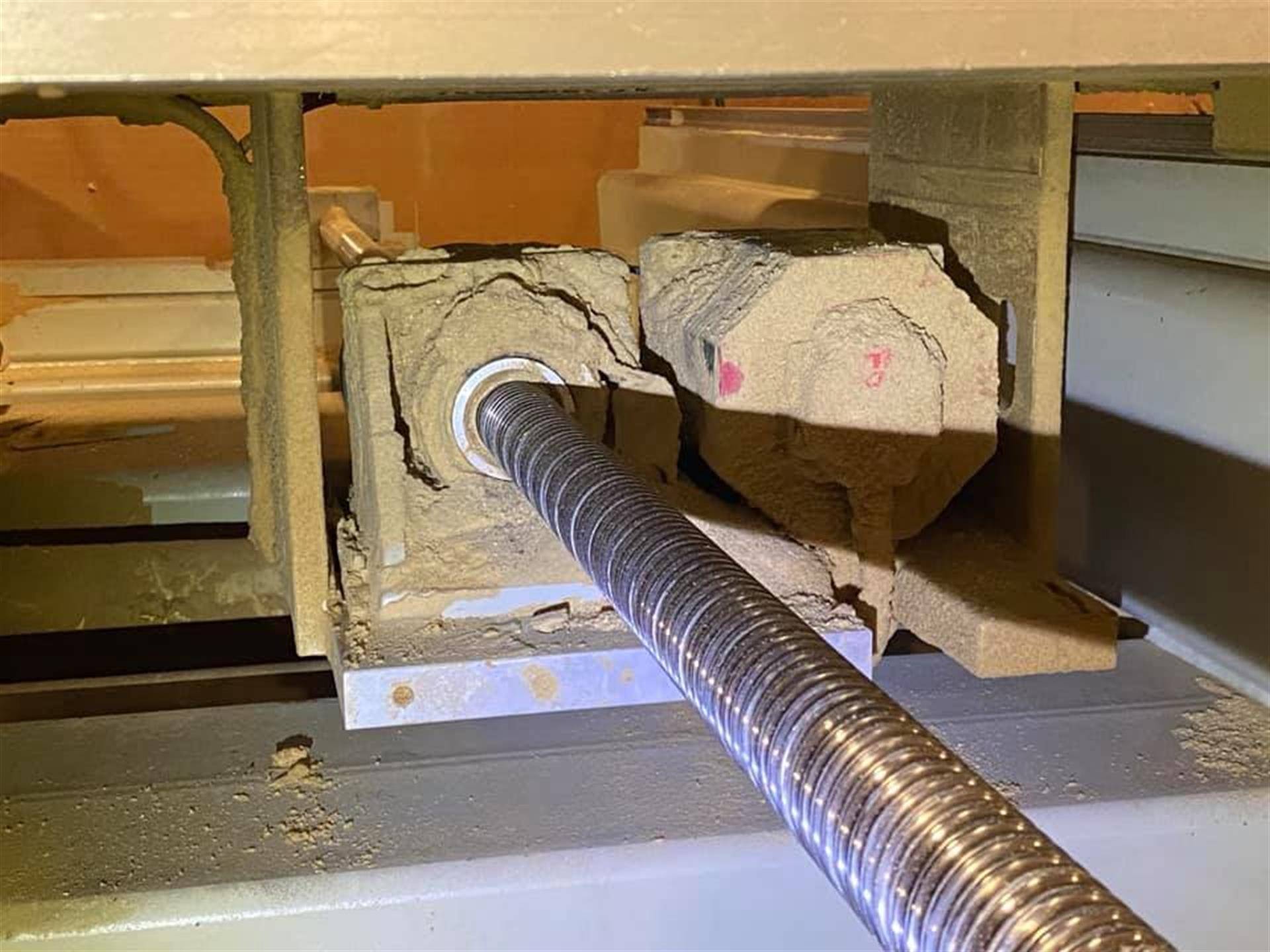

This image shows a problem we often encounter with the X-Axis table which persists after the ball screw has been refurbished, properly aligned, and retensioned. Look at the concrete floor in the picture. Notice that the mache sits on multiple slabs. Often, when the floor is engineered and poured properly, floor shift is not an issue. But in some areas, solid conditions and moisture levels cause these slabs to move. While some might dismiss the effects of slab movement, it can twist your machine into a helix where the linear way guide rails are not parallel and share the same plane as each other and the ballscrew. It is important to check your machine level every few months and especially after drastic temperature changes or rain/drought periods. This happens more often than most realize.

Komo Fusion Machines are popular in many industries. We typically see them in high volume furniture and cabinetry applications. This is one of our customers with a bay of 6 Fusion machines, with another three coming. The maintenance staff here is top notch. Over the years, they have bought replacement Bosch Rexroth ball screws because the original ones locked up and failed. Without knowing options, they thought the only way to get their machine back in production was through KOMO, often waiting months for replacements to arrive. We can get your routers cutting again fast. Because this facility saved their old ball screws, we are able to refurbish them as replacements that can be quickly switched out and repeatedly refurbished for a fraction of the replacement cost saving both time and money.

Top view picture of a damaged Bosch Rexroth Z-Axis ballscrew on a Komo Fusion CNC Router. In this case, the original OEM plastic ball bearing recirculation inserts failed causing all the ball bearings to fall out with what was left of the inserts, snap rings, and seals. Notice the Lube line attached, with oil clearing inside. Often maintenance techs get a false impression that their KOMO ball screws are getting lubrication when they are not. Saw dust and debris gets packed up into the ball nut preventing lube from flowing. Once the lubrication stops, the interior parts of the ball nut start to wear out and eventually fail. KOMO’s solution is to sell you a new ball screw with a variable lead time for part arrival and installation. We can come repair your screws in place, generally within a few days to a few weeks at a vastly lower cost. If you do receive a replacement screw, save your old one and we will come by and repair it for a spare so you can swap them out when needed with only a few hours of downtime.

A common sight on KOMO CNC routers which have chronic noise and looseness issues. While operators often are great at keeping machines externally clean, often the areas under covers are ignored. Cleaning out under the X Axis Table is critical for longevity of function. Sawdust build up like this destroys the plastic internals of the Bosch Rexoth ball screws used in KOMO Fusion and Extreme machines.