Mazak Lasers

Ballscrew Guys have in depth experience with on site field service of ball screws and bearing based CNC motion systems of MAZAK lasers. Our Flat Rate Priced accurizing and refurbishment services can be completed in one production shift. Minimizing your production downtime while simultaneously increasing your productivity afterward.

The primary areas of concern are the lubrication systems for the X & Y Axis ball screws and the linear way guide rails and bearing blocks, also commonly referred to as sliders or skates. The linear way guides do not need service as often as the ball screws but may be an important factor if your machine is experiencing servo strain or stuttering during cuts.

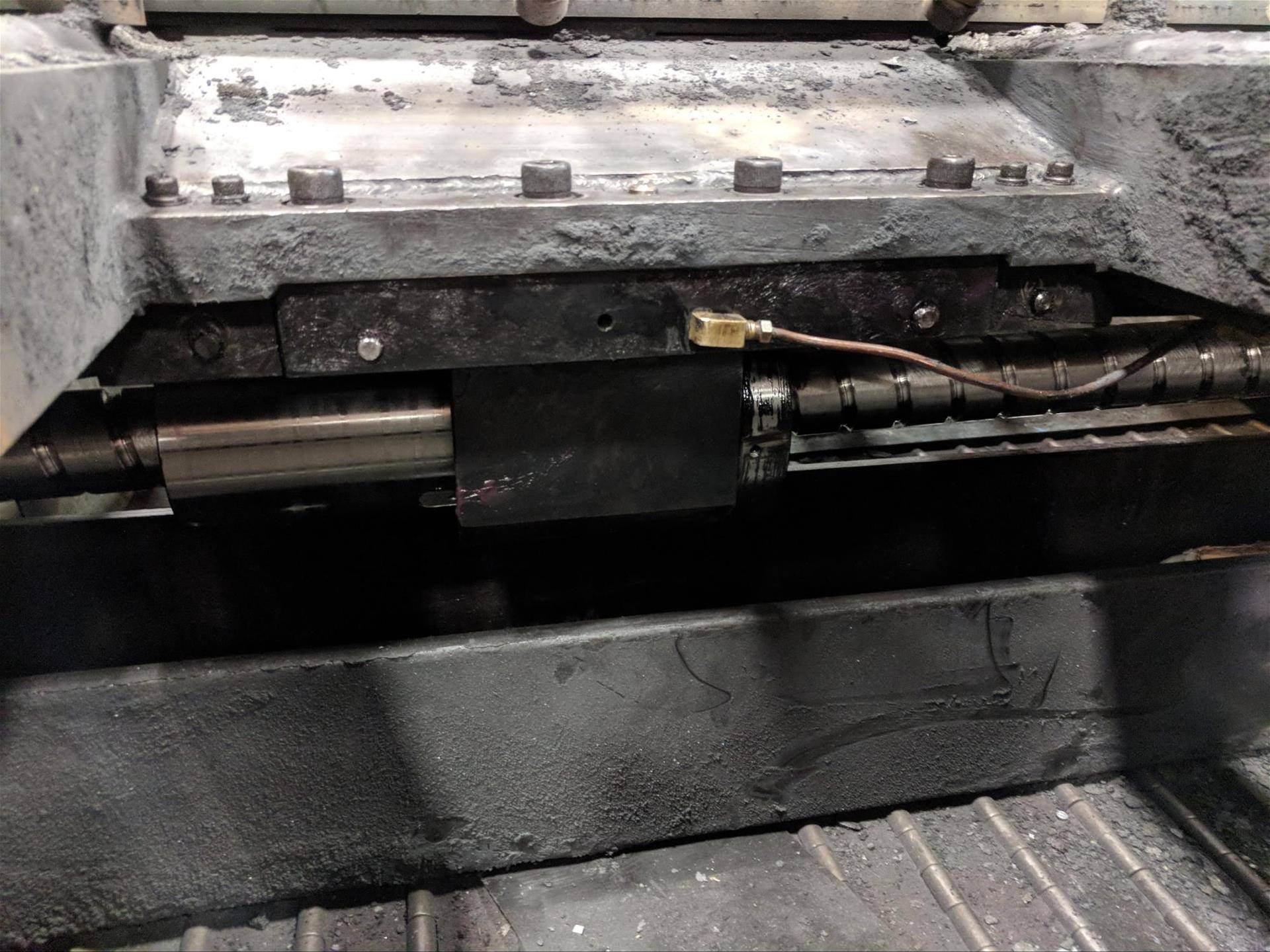

The X-Axis ball screw is serviced through the cutting table. It’s important to know which slats are removed, what positions and sequence required to drop the ball screw protective pan, safety move the X-Axis spring cover, remove the copper lube line, then dial the ball screw nut off the table yoke properly.

The most common reasons why X-Axis ball screws on the MAZAK series of lasers become loose and prematurely worn are shown in this picture. This is a side view of the X-Axis ball screw yoke. Notice the chill hardened steel dust build up on all the surfaces. This is the main contaminate found which migrates into the X and Y Axis bearing systems of MAZAK Lasers.

Look at the copper lubrication line. Notice its lack of support on the machine. It already has bends and twists in it. This lubrication system design is rigid, so when cutting drops not being adequately removed by the conveyor get snagged under the table, the line will often kink, have a hole cut into it by harder metals, or just plain snap. Because the line is relatively hidden from the operator, it can commonly go unnoticed for years. During which time the ball screw nut is starved for lubrication and gets premature wear.

Look at the copper lubrication line. Notice its lack of support on the machine. It already has bends and twists in it. This lubrication system design is rigid, so when cutting drops not being adequately removed by the conveyor get snagged under the table, the line will often kink, have a hole cut into it by harder metals, or just plain snap. Because the line is relatively hidden from the operator, it can commonly go unnoticed for years. During which time the ball screw nut is starved for lubrication and gets premature wear.

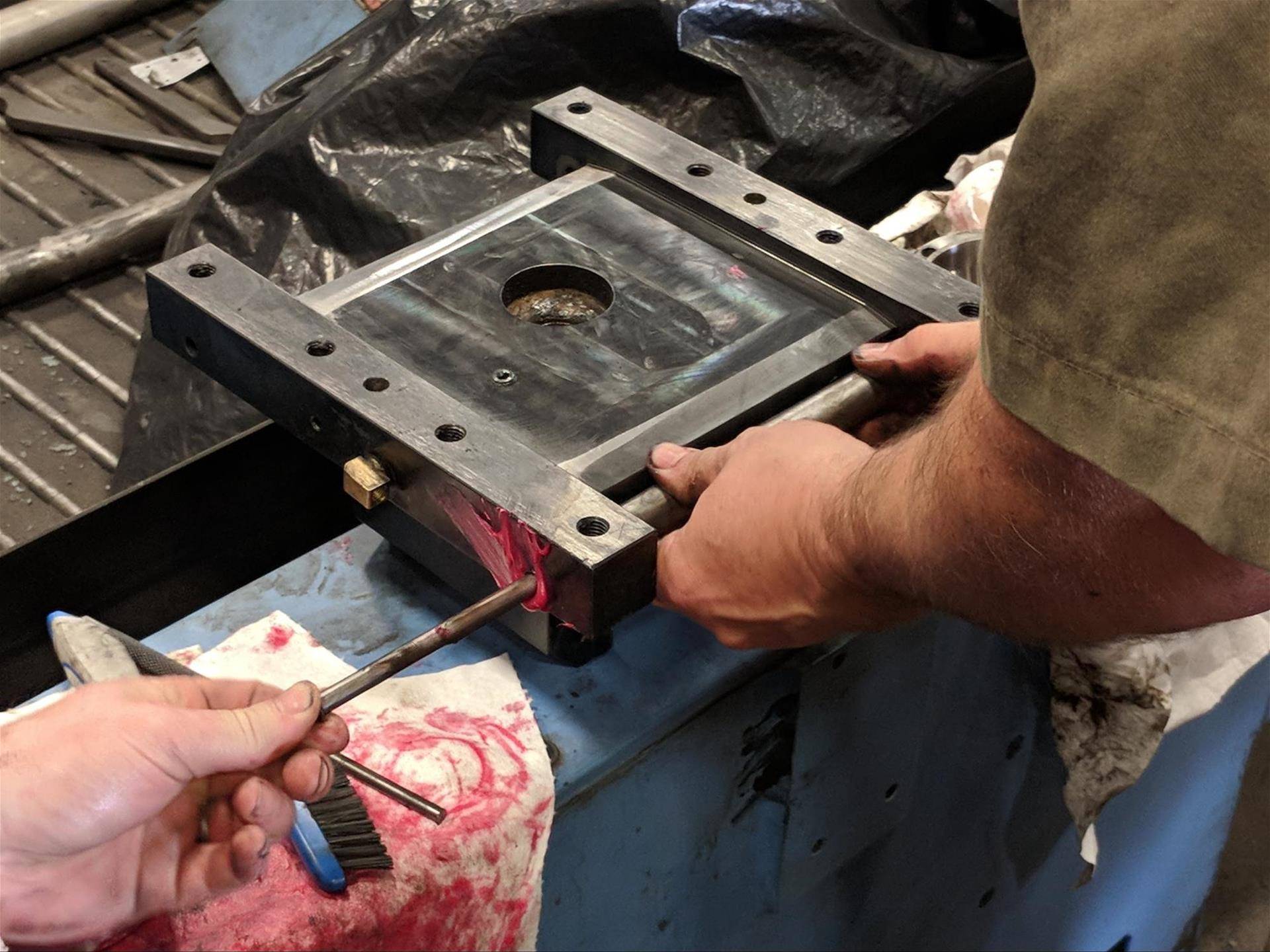

Above shown is the X-Axis ball screw yoke which connects the ball screw nut to the table. This is a special assembly with rollers that thread the protective X-Axis spring cover through the table. The OEM rollers from MAZAK are expensive and contain needle bearings with plastic spacer cages. These cages become contaminated over time causing the needle bearings inside to seize and break. This then causes the rollers guiding the ribbon like spring cover to roll off center, eventually damaging the spring cover.

We have extensive experience at handling these problems but must inform all that this level of X-Axis refurbishment is not typically part of our regular X-Axis flat rate services.

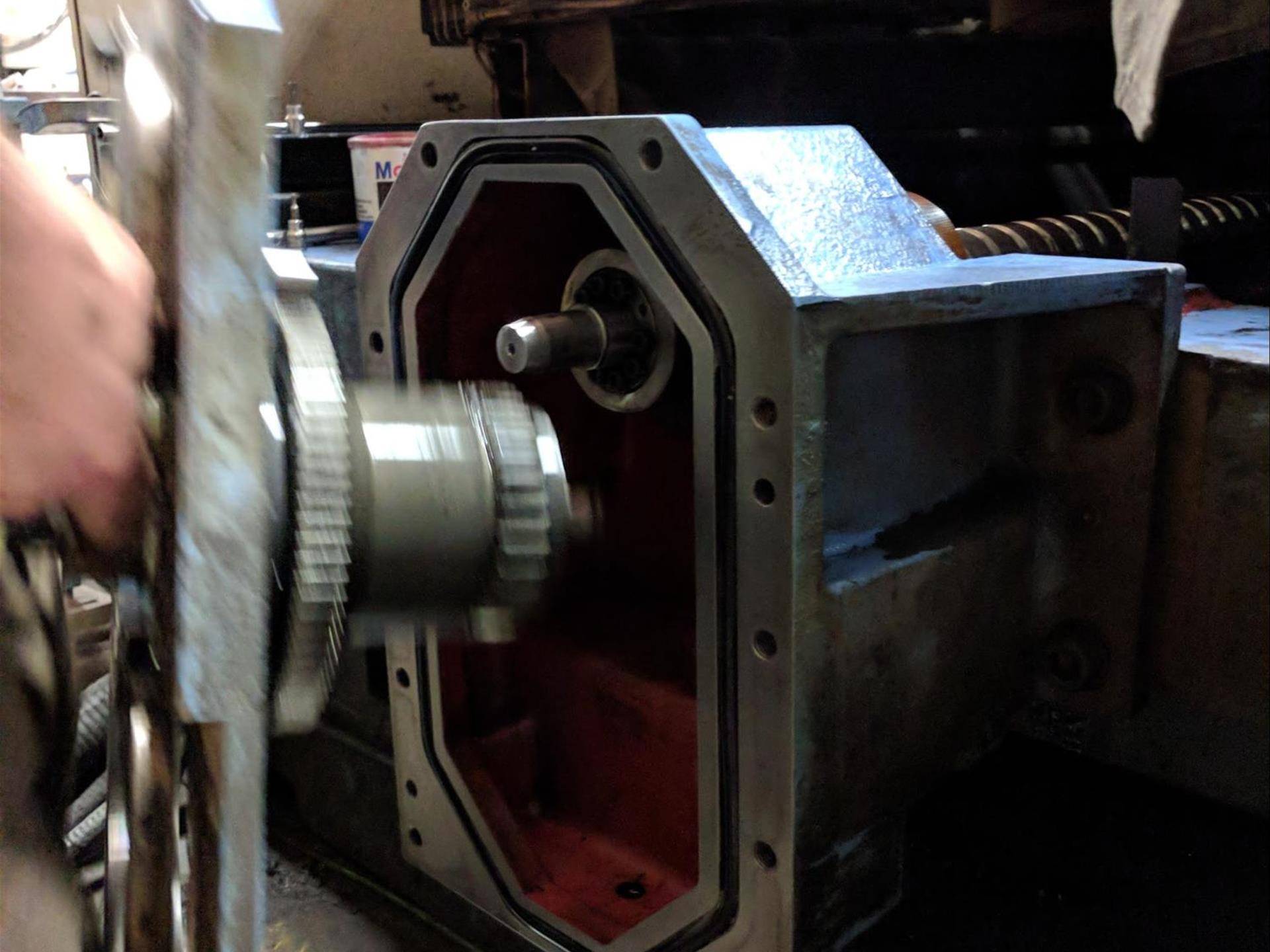

This is the outboard end bearing housing for the X-Axis ball screw. Quite often the end bearings on the X and Y axis motion systems need replacement. When they were installed from the factory, they are greased and left as a sealed system. Over time, grit and contamination migrates into the end bearings from the ball screw. Eventually this wears the outside end bearings and causes the raceways to get pitting. This later turns into audible noise similar to the grumble whine of bad wheel bearing found in a car. If left unserviced the ball bearing spacer cage inside disintegrates and the end support of the ball screw develops additional friction causing servo motor strain, looseness along the ball screw axis, or seizure of the bearing parts. End bearing services are typically not part of our flat rate X-Axis ball screw service packages.

Above is a picture of the outboard end bearings taken from the X-Axis of a Mazak laser. On this particular laser, the bearing stack consists of 4 Nachi bearing packs, each having to be positioned and aligned in a particular order to work properly. We cannot express enough the number of times we have gone to service ball screw systems with end bearings installed by factory maintenance staff incorrectly, causing axis motion problems. It is critical that the direction and stack order of these bearings be correct for reliable machine function.

The replacement of the motor side end bearings of Mazak Lasers takes quite a bit longer than the outboard side. Gear oil must be be drained before the rear gearbox and motor assembly can be removed. The primary mechanical problem mandating this service is the replacement of the end bearings. Occasionally systems with gasket leaks around the gearbox or excessive contamination and friction in their ball screws and linear way guide systems may have drive wear on the teeth of the internal drive cogs. This has been a very uncommon culprit in our experience to explaining looseness or hesitation flaws while cutting during axis directional changes. Essentially, “chatter” in the gear teeth mesh gets transmitted through the screw causing a cutting issue.

A typical Y-Axis of a Mazak laser. The Y-Axis often receives the most contamination. Operators who regularly wipe down and clean this area typically will not experience the same wear as those who do not clean. Notice the build-up on the linear ways. This material just destroys bearing systems. Believe it or not, this picture was taken after the first cleaning pass was made. There was still much scrubbing involved to get it right.

The Y-Axis after some more cleaning. The dual track split nut was separated in halves for inspection. This ball nut has two sides pushed apart by a solid spacer shim secured in between the two halves. It is important when new oversize bearings are installed that the spherical geometry of the new ball removes dead-band space of the assembled ball nut only when the two halves are reconnected with the spacer shim installed. Too often we have seen replacement bearings placed inside the ball nut on these styles of assemblies, only to have the ball bearings crushed when the two nut halves are forced together upon reassembly.

Pittsburgh Patti cleaning the crud out of a MAZAK Laser Y-Axis at a machine located in Newark, New Jersey. Ballscrew Guys have a diverse mix of technicians located all across the United States.

The most common motion system issues with the MAZAK Laser are ball screw wear and contamination in the outboard end bearings. Every ballscrew will spin between two sets of bearings. One motor-side. The other outboard. The Outboard Bearing stacks on MAZAK lasers are typically located more where the cutting action actually takes place. These being typically the ones which go first. The Y-Axis being the most common. In this picture, the Y-Axis end bearing was destroyed. When the protective seating cap was removed, you could see rust and debris, but not a single trace of lubrication oil or grease. This is why Ballscrew Guys always does an Outboard End Bearing Inspection of every MAZAK ball screw service we make.

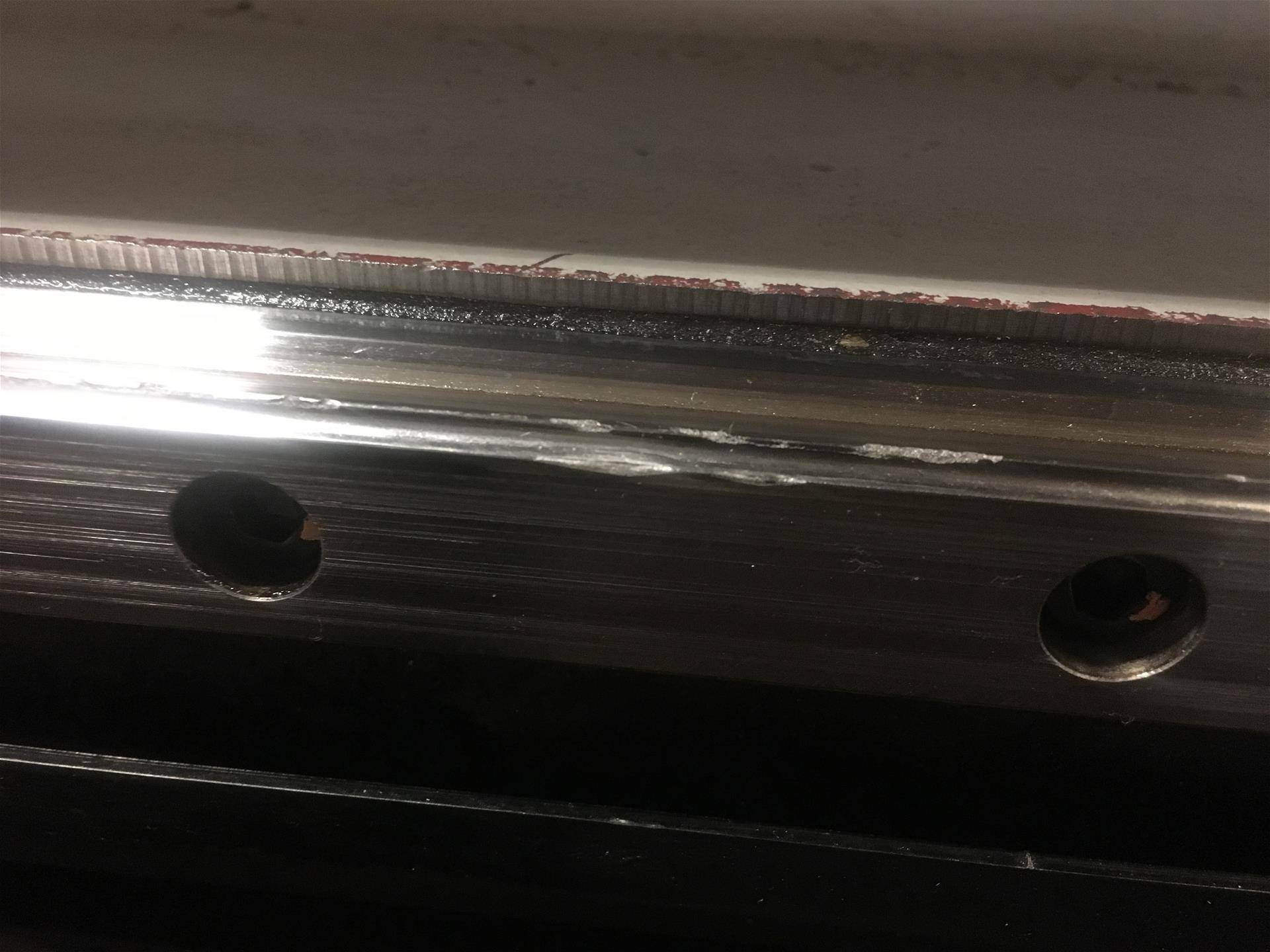

This is a damaged THK Linear Way Guide Rail which has experienced damage. On many of the MAZAK laser systems, there is a vinyl protective cover on the Y-Axis, While this does protect bearing components from contamination, it also prevents visual inspection of the bearing surfaces. This rail was damaged by a worn out Linear Way Guide Block. The plastic cap on the end wore out, spilling all the bearings inside. This caused the block to scrape along the rail, damaging it beyond repair. New rails and sliders were required to fix this. The root cause of this failure was lack of lubrication to the linear way guide sliders.

X-Axis ball nut as it was disconnected from the table in a Super Turbo X510 MkII. This split/dual ball nut was loose. Notice the black coating on the back half (follower) of the ballnut. The front half of the ballnut is actually protected in the take yoke housing. The back end however collects debris and crud. These split nut ball screw types have a space shim between them, causing each half of the ball nut to ride on a different side of the bearing track. Contamination causes the follower side to wear at a different rate than the flange side. Once the spacer shim becomes loose in between these dual ball nut systems, the machine accuracy drops considerably.

Contamination and debris we often pull out of the Y-Axis ball nut and ball screw. It is critical that your CNC Motion Systems receive regular cleaning and lubrication service to stay accurate and reliable.

Replacing the THK Linear Way Guide Rails and Bearing Blocks on the Y-Axis. We disconnected the lower blocks from the Laser Head assembly. These blocks were damaged and worn out because of a lack grease. They rock back and forth freely on the rail and were causing cut "stuttering" along Y-Axis cuts.

The lower rail and slider blocks were destroyed. These were removed from the machine. The location and bolt holes for mounting the new rail were cleaned and scrubbed smooth. Making sure there is no contamination or debris behind the Guide Rail as it is set, aligned, and torque wrenched into place with brand new bolts.

The worst part of a Laser Alignment Rail job is removing the Y-Axis Linear Way Guide Blocks. Disassembling the laser head itself comes with time and risks. Every part you remove to gain access to the bolts is a piece to the laser that may have to be reset or recalibrated for accurate cutting. This image may make it seem like you can just make a stubby Allen wrench and get the blocks out. We wish it was that easy.