Amada EMLK

The Amada EMLK 3610nt is a combination laser/turret punch system that uses a servo drive punching system and a hybrid laser with a Fanuc 4000-watt resonator. This machine offers high productivity, flexibility and reliability for sheet metal processing. We have extensive experience in servicing the ball screw and linear motion systems on this machine, which are essential for its accuracy and performance. We can provide field service CNC ball screw repair for this machine with minimal downtime and maximum quality.

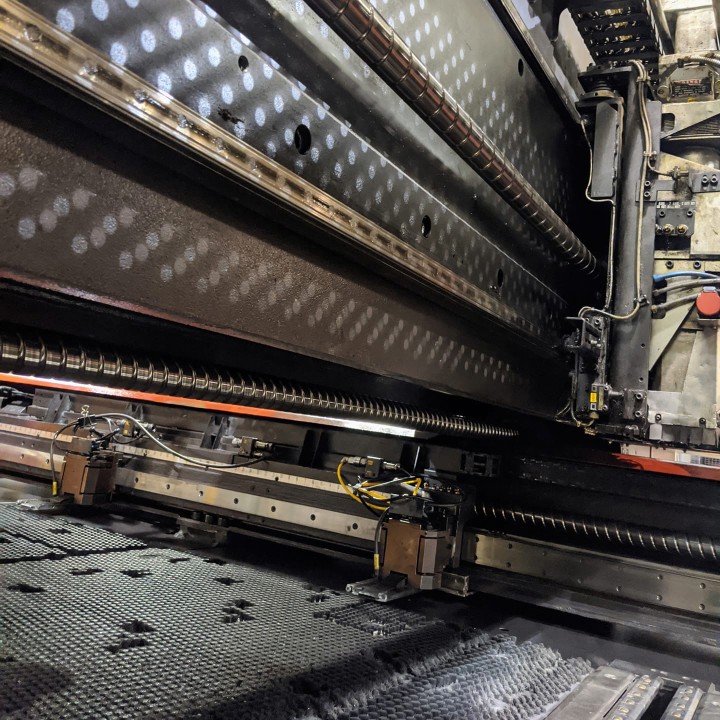

This image shows three of the four ball screws in an Amada EMLK 3610nt combination laser and turret punch. The bottom ball screw is the X Axis material handler ball screw. The middle ball screw perpendicular to the X Axis is the Y-Punch Axis. The top ball screw is the Y-Laser Axis. Although they look similar, each has unique issues to address when restoring cut and punch accuracy. Most of the time, when field servicing these machines, we can rebuild the ball screws while still inside the machine. However, the Amada is different. To effectively refurbish the ball screws to like-new performance, they must be removed from the machine.

This is the Y-L or Y Laser Axis ball nut found in an Amada EMLK 3610nt. It was just disconnected from the laser head yoke inside the machine. This is a Japanese ball screw component manufactured by THK. This particular ball nut has twin sets of wipers on both sides, but no real wiper seal. The black ring on both sides of the ball nut is not a seal and does not keep out the black laser dust you see on the ball nut body. This dust migrates into the ball nut and destroys it. Regular maintenance of pumped grease is required to flush out this dust. The lack of lube, mixed with laser dust, is the reason why the ball bearings inside the ball nut wear out prematurely. The ball bearings are ground down to smaller sizes, causing looseness. This degradation of ball bearings later manifests itself into poor cut quality of the laser itself.

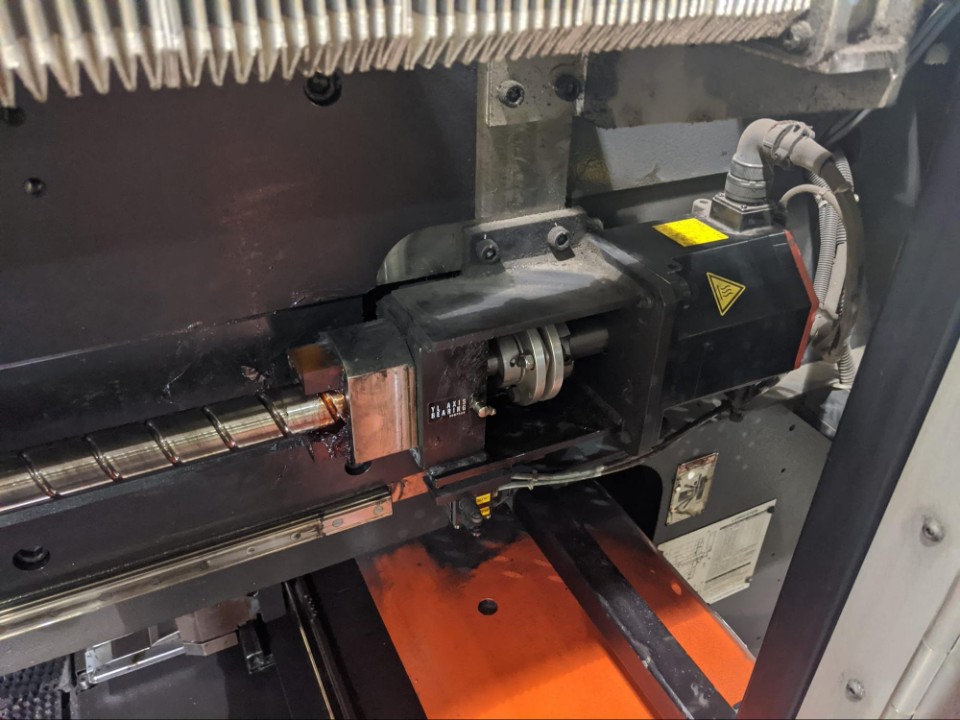

This is the FANUC servo and motor coupling connected to the Y-L or Y Laser ball screw on an Amada EMLK 3610. To service the ball screw on these machines, they must be removed. If the screw shaft is being pulled, it is prudent to replace the end bearings while our field service technicians are there at your facility. Notice the zerk fitting on the end bearing housing. It is there for a reason, but too often it is ignored.

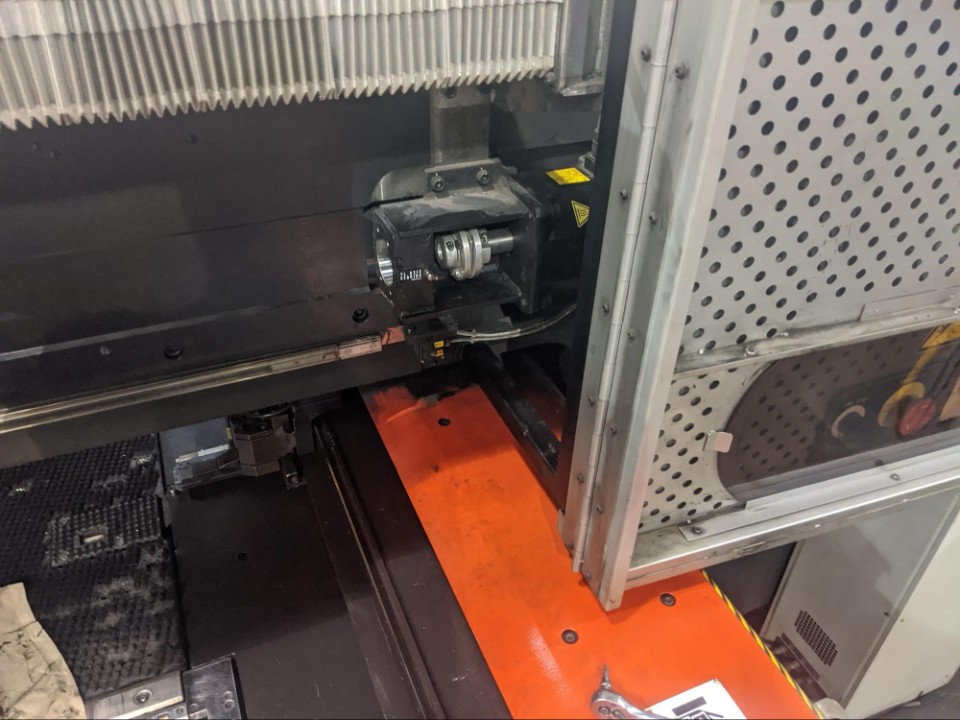

This is the empty area left behind when the Y-L or Y Laser Axis ball screw assembly is removed for service. We clean out the motor housing and prepare the assembly for new end bearings. The THK ball screw is taken out of this Amada EMLK 3610nt and rebuilt on jack stands next to the machine. After refurbishment, we reinstall and lubricate the ball screw.

This photo shows the Y Laser Axis that has been pulled in this Amada EMLK 3610nt. When we field service CNC ball screw repair to this Amada laser turret punch system, we have to take the ball screws out of the machine to rebuild them. This is one of the reasons it takes longer for us to service the EMLK line. On many other laser systems, we can refurbish multiple axes in a single work shift. But on this Amada system, more man hours are required. We typically plan on one shift per axis, assuming we have full repair access, and the machine is powered. If the machine is pressed up against walls or not functioning due to transport or down controller, the repair will take longer.

This photo shows the X Axis covers removed on an Amada EMLK 3610nt Laser Turret Punch. This ball screw assembly is tightly packed into a cavity within the sheet material handler. Notice the cable bearer capping it off. This design requires ball screw removal to service and refurbish. The lubrication line is a clear plastic, which is a nice change from earlier Amada laser systems where they always used copper lubrication lines. While the copper lines are way more impressive and fancier, the plastic lines here are easy to move around for service and easier to repair.

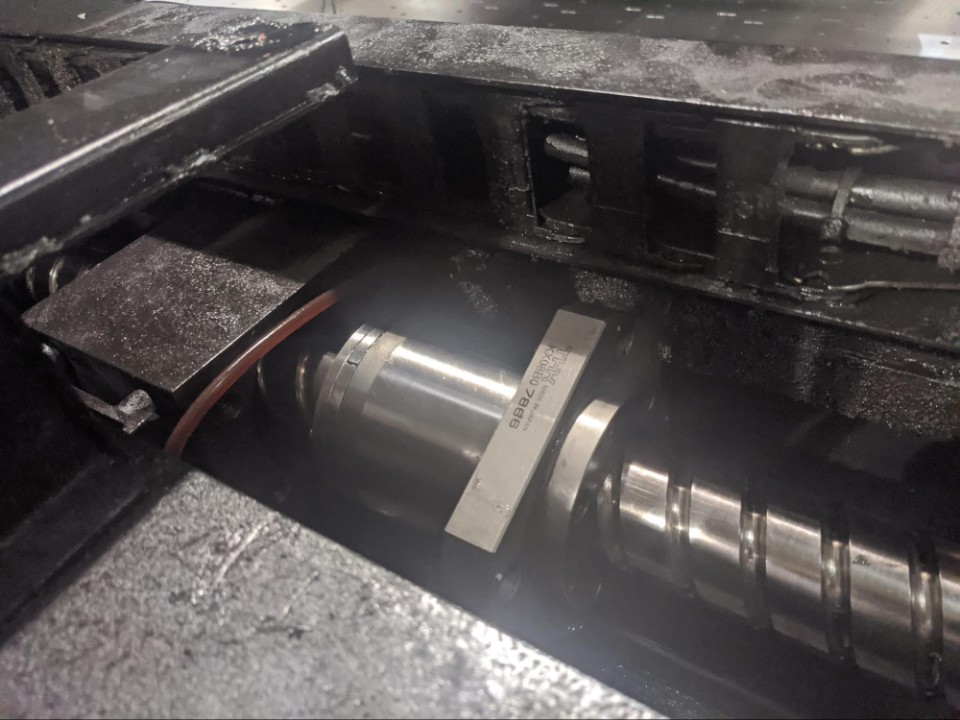

This is the X Axis running with a THK ball nut on an Amada EMLK 3610nt Laser Turret Punch (Model THK KX08B0 7866). The ball nut was damaged when the anti-vibration support slider sheared from lack of lubrication. The steel channel spacer from this assembly popped up and destroyed the two wiper seals on the flange side of the ball nut.

This is a piece of an X Axis part found within an Amada EMLK 3610nt Laser Turret Punch. It belongs to the anti-vibration support slider, which operates in tandem with the X Axis ball screw, moving back and forth on its own dedicated linear way guide rail. This particular part failed inside the machine because there is no real way to lubricate it. When it failed, it jammed up the X Axis but then settled down out of the way, where the machine operated with the problem largely unnoticed until they wanted to start cutting and punching high speed on aluminum sheets. This is another critical system in the EMLK machine line, which often the machine owners and operators don’t really know about. It needs service and cleaning regularly, or it can be detrimental to your machine.

This is an X Axis Service on an Amada EMLK 3610nt Laser Turret Punch. The outboard end bearing assembly had been disconnected and removed. That is part of the anti-vibration support slider, which operates in tandem with the X Axis ball screw. This one was damaged and is being replaced along with refurbishment to the X Axis ball screw. BallscrewGuys are specialists at field service rebuilding your machine, providing mobile CNC ball screw repair.