Shop Sabre Router

Shop Sabre IS612 CNC Router. Neat machine. The IS models are their industrial series. This model is super easy to work on and service. Problem is, the twin X-Axis ball screws on either side of the Y-Axis Gantry are exposed. This is a good thing if your operator is mindful about visual inspection, cleaning and lubricating. The not so great thing is that the ball nuts on these screws can suck up plastic and debris. In this case, clogging the ball screw assembly so bad it jams up and seizes. On this machine it seized so bad, it broke two bolts holding the gantry assembly on. Ballscrew Guys was called out for emergency field service repair. We are your CNC ball screw repair specialists.

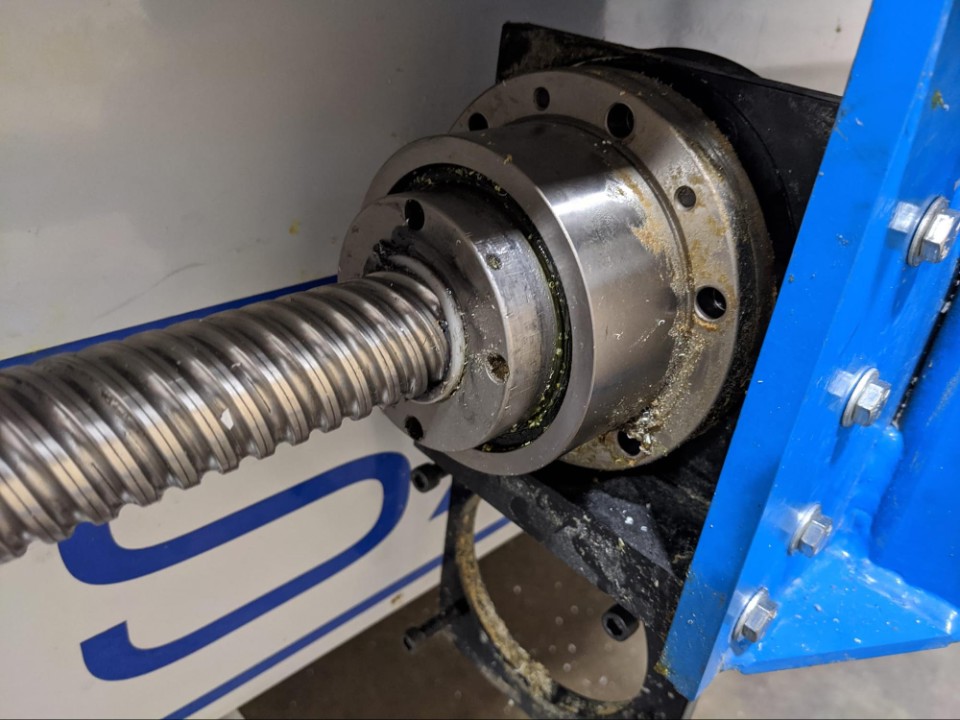

The X-Axis ball screw assembly found on the side of a Shop Sabre IS612 CNC Router. This machine model has dual X-Axis ball screws. They use a good quality Hiwin ball nut with an external rotation bearing. All metal internal parts with a primary seal and secondary wiper system. This system rotates along its raceway helix simultaneously on multiple tracks. Has an external grease fitting which might be missed, on top of the rotation bearing flange. What impressed me the most about this ball nut is it has ten large diameter internal lubrication holes milled into the ball nut body. This makes it easy for grease to migrate from the rotation bearing into the ball screw nut. A Bosch-Rexroth of similar design only uses two of way smaller diameter. Holes that clogs up very easy in router applications. Good job, Hiwin! This ball nut was built to be a super durable system for router applications.

Cleaning out the debris from a Hiwin Ball screw used as dual X-Axis screws for a Shop Sabre IS612 CNC Router. This assembly sucked up some plastic film material and completely seized. It was rather challenging to free it from the ball screw shaft without damaging raceways. But Ballscrew Guys got it done. Here you can see the dual track system used. In all of out refurbishments, we clean out all the components. Inspect and replace seals/wipers as needed. Put in new slightly oversized ball bearings to restore accuracy. Then make sure the lubrication delivery system is working and flowing properly.